Unveiling Micro Industries: A Legacy of Excellence

Our journey began with a vision to revolutionize material handling within Indian industries. With a team of passionate engineers and a commitment to innovation, we've carved a niche for ourselves. We prioritize understanding our clients' specific needs and crafting customized conveyor solutions that enhance efficiency and productivity.

Beyond Standard Conveyors: Customization is Our Strength

Micro Industries understands that a one-size-fits-all approach doesn't work in today's dynamic industrial landscape. We excel in customizing our conveyor systems to seamlessly integrate into existing workflows. This may involve tailoring belt types, modifying conveyor lengths and widths, incorporating curves and inclines, or integrating with sorting and packaging systems.

Our team of experts collaborates closely with clients to understand their specific needs and challenges. Through detailed consultations, we design and manufacture conveyor systems that perfectly complement their existing infrastructure and operations

Our Extensive Conveyor Portfolio

Micro Industries boasts a versatile conveyor product line, catering to a wide range of applications. Here's a glimpse into some of our most sought-after offerings:

Belt Conveyors: These workhorses of the industry are ideal for transporting a variety of materials, from bulk goods to packaged items. We offer a variety of belt types and widths to accommodate diverse requirements.

Roller Conveyors: Perfect for conveying unit loads, roller conveyors provide smooth and efficient movement for boxes, pallets, and crates. We provide options with gravity rollers, powered rollers, and even accumulation zones for optimized flow control.

Chain Conveyors: Designed for heavy-duty applications or conveying products on inclines, chain conveyors offer robust construction and reliable performance.

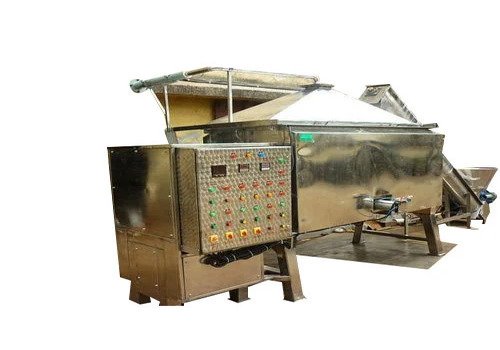

Screw Conveyors: Ideal for bulk material handling in tight spaces, screw conveyors utilize a rotating screw to efficiently move materials in a continuous flow.

Overhead Conveyors: Perfect for maximizing space utilization, overhead conveyors suspend materials from the ceiling, freeing up valuable floor space.

Exceptional Customer Service: Building Long-Term Partnerships

We believe in fostering long-term relationships with our clients. Our commitment extends beyond delivering high-quality conveyors. We offer comprehensive customer service, including:

Pre-Sales Consultation: Our experts provide in-depth consultation to understand your requirements and recommend the most suitable conveyor solution.

Installation and Commissioning: We provide skilled personnel for professional installation and commissioning, ensuring smooth integration into your production line.

After-Sales Support: Our dedicated team offers prompt after-sales support, including maintenance services and readily available spare parts.

Frequently Asked Questions

What industries do your conveyor systems cater to?

Our conveyor solutions find application in a diverse range of industries, including manufacturing, warehousing, pharmaceuticals, food processing, automotive, and e-commerce fulfillment centers.

Can you provide spare parts for your conveyor systems?

Absolutely. We maintain a comprehensive inventory of spare parts for all our conveyor models.

Do you offer installation services?

Yes, we offer professional installation and commissioning services by trained technicians to ensure optimal performance of your conveyor system.

How do I choose the right conveyor system for my needs?

Our team of experts is happy to assist you in selecting the most suitable conveyor system based on your specific material handling requirements, product type, production volume, and budget constraints. We recommend scheduling a consultation to discuss your unique needs.

What are the benefits of using a customized conveyor system?

Customized conveyor systems offer several advantages, including:

Improved Efficiency: Streamlined workflows and optimized material handling lead to increased productivity.

Space Optimization: We can design conveyors to fit seamlessly into existing layouts, maximizing space utilization.

Reduced Labor Costs: Automated material handling reduces reliance on manual labor, lowering operational costs.

.jpg)